Discover the Versatile Uses of Membrane Layer Switch Over in Modern Electronic Devices

In the world of contemporary electronics, the application of membrane layer switches is extremely substantial, spanning from sleek consumer devices to vital clinical tools. These slim, versatile interfaces not just simplify device operation with their responsive responsiveness but additionally significantly improve longevity by resisting ecological hazards like wetness and dirt. As markets remain to develop, the assimilation of membrane layer switches in equipment design is crucial, promising not just to fulfill but go beyond the rigorous needs of both performance and visual appeal. Discover a lot more about just how these parts are forming the future of innovation.

Discovering the Role of Membrane Layer Switches Over in Consumer Electronic Devices

Why are membrane switches over so prevalent in consumer electronics? Membrane buttons are cost-effective to make, making them an eye-catching option for high-volume production common in customer electronic devices.

Additionally, these buttons are recognized for their longevity and low upkeep. From microwave stoves to remote controls, membrane buttons give a functional, easy to use user interface that supports the vibrant nature of customer electronics.

Membrane Layer Switches Over in Medical Gadgets: Enhancing Customer User Interfaces

Membrane layer buttons also play a considerable duty in the world of clinical tools, where they boost user interfaces with their unique benefits. The smooth, covered surface area of membrane layer changes allows for very easy sanitation, lessening the danger of contamination and spread of virus.

Membrane layer buttons likewise add to the longevity of clinical gadgets. Their resistance to contaminants and liquids ensures that essential equipment stays functional in different scientific settings, consisting of surgeries where direct exposure to liquids is usual. This longevity, combined with responsive responses and inconspicuous layout, makes membrane changes an indispensable component in enhancing the efficiency and safety and security of clinical device user interfaces.

The Effect of Membrane Turns On Industrial Tools Style

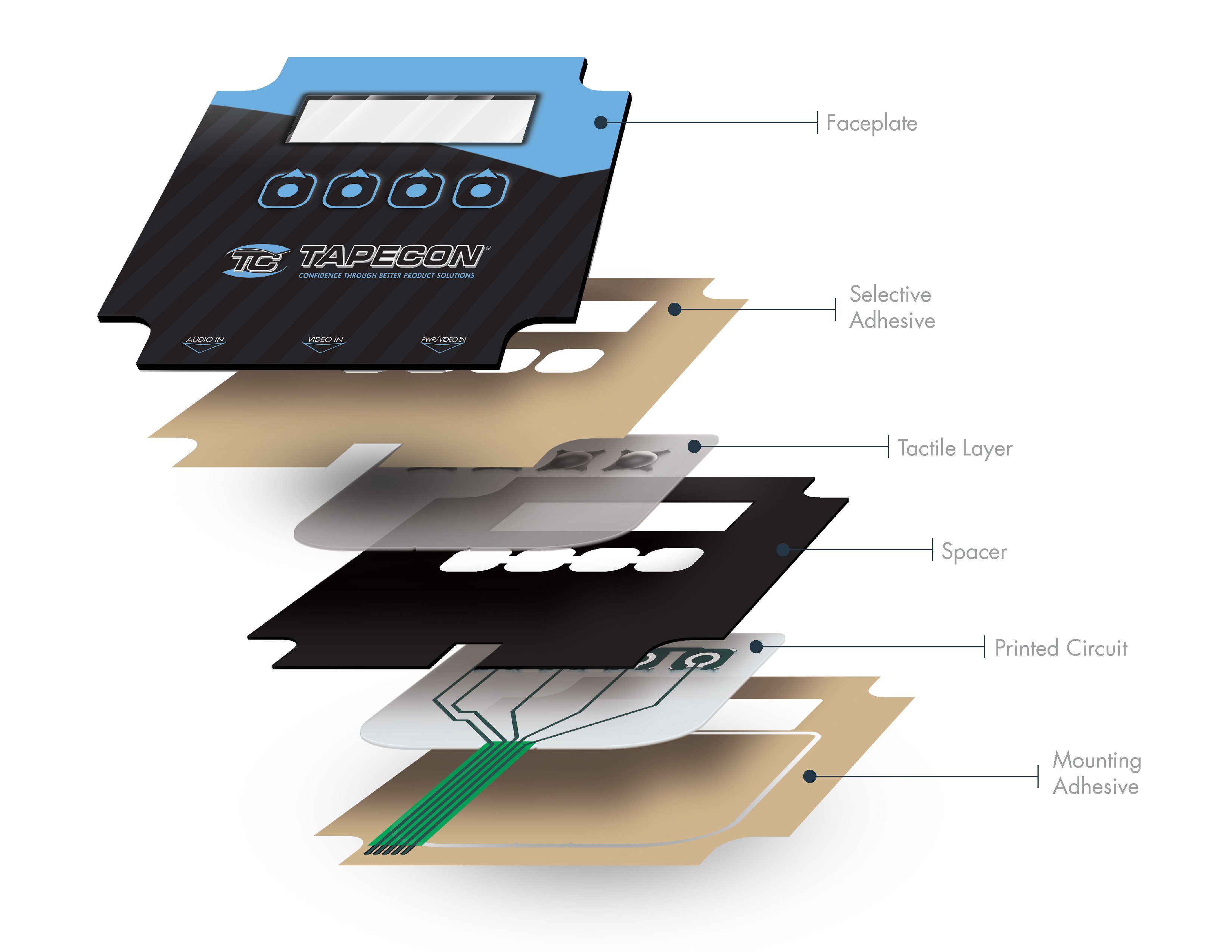

In the world of industrial devices design, the incorporation of membrane switches has noted a substantial advancement. These buttons have actually changed just how producers come close to interface functionalities, providing a mix of durability and flexibility that is necessary in rough settings. Read More Here The slim account of membrane switches over permits more portable machine layouts, while their resistance to water, dust, and chemical impurities makes them perfect for industrial setups. This versatility has facilitated the advancement of equipment that is not just extra robust however additionally much easier to maintain and tidy, consequently decreasing downtime and functional costs.

In addition, the customizability of membrane layer changes allows designers to integrate certain tactile comments and visual overlays that enhance the individual experience and rise performance. This assimilation sustains operators in accomplishing precision control over complex equipment. The general effect is a considerable improvement in the functionality, integrity, and user-friendliness of commercial tools, straightening with the increasing needs for technical innovation and operational effectiveness in modern-day markets.

Final Thought

Membrane switches have actually revolutionized modern electronic devices, supplying sleek, resilient, and customizable user interfaces across various see this site markets. This innovation not only satisfies the demanding problems of different areas yet likewise dramatically boosts customer experience, making membrane switches over a keystone of contemporary digital layout.

In the realm of modern electronic devices, the application of membrane switches is remarkably extensive, covering from streamlined consumer gadgets to crucial clinical tools.Why are membrane changes so common in consumer electronic devices? Membrane buttons are economical to manufacture, making them an appealing alternative for high-volume production regular in customer electronics. From microwave ovens to remote controls, membrane layer switches provide a functional, easy to use user interface that supports the dynamic click site nature of customer electronic devices.

Comments on “Upgrade Your Equipment Using Membrane Switch for High-Precision Applications”